Wanting to find what pump configuration works best for your application but finding the wealth of options daunting? Graco's Process Pump Selector is a fantastic tool to help you navigate these options. Not only that, here you'll also find technical specs, performance charts and a listing of key spares for your pump to ensure you know everything about your pump's performance and how to maximise it's lifespan.

Chris Cooper

- Posted: February 05, 2021Categories: Air-Operated Double Diaphragm Pumps BlogRead More

- Posted: February 05, 2021Categories: Air-Operated Double Diaphragm Pumps BlogRead More

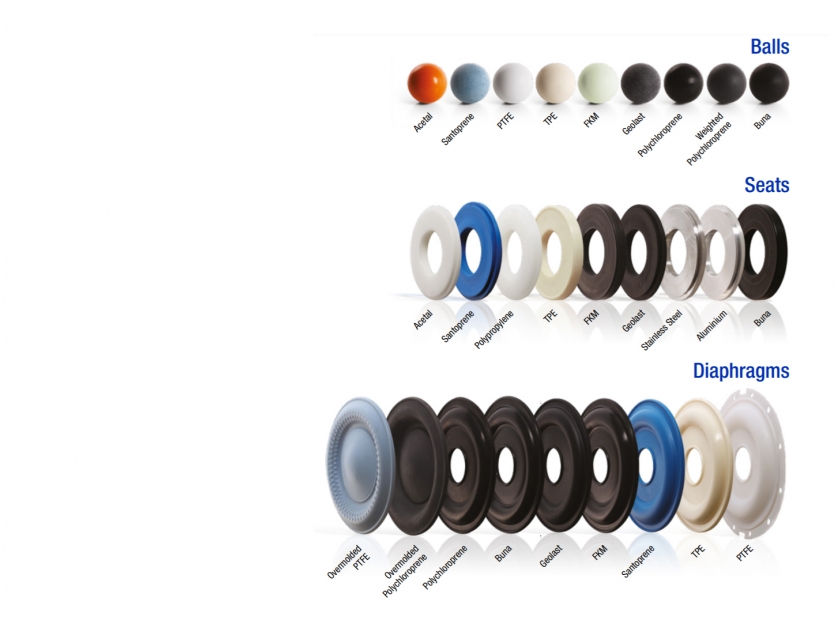

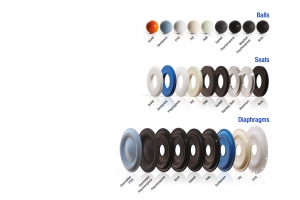

Our double-diaphragm pumps have so many great options. Choose from a wide selection of ball, seat and diaphragm materials to ensure that your next pump is perfectly tailored for your application, including the transferring of corrosive and abrasive materials and key fluids including:

- Paints, stains, coatings, inks and dyes

- Chemicals

- Acids

- Corrosive and abrasive fluids

- Lubricants

- Ceramic glazes

- Sludge, slurry and waste fluid

- Soaps, detergents and solvents

- General and advanced mining applications

- Posted: January 15, 2021Read More

Challenge:

An energy service company that refurbishes catalytic converters for power plants previously used two 29 mm peristaltic pumps to move lime slurry at 20% to 30% concentration for each of their two water treatment applications. These two peristaltic hose pumps were taking up a large portion of the workspace. In addition, the hoses on the peristaltic pumps needed to be replaced every 2 to 6 weeks, which was backing up production and increasing maintenance and repair costs. The company was looking for a solution to use their space more efficiently, decrease maintenance, and still maintain production flow rates.

Solution:

By installing one Husky 1050e from Graco into their water treatment facility, the energy service company was able to shut down both peristaltic pumps on a line and rely solely on the 1050e for lime slurry supply. They were surprised to discover that the Husky 1050e could achieve the same flow rates as the two pumps that it replaced

- Posted: January 15, 2021Read More

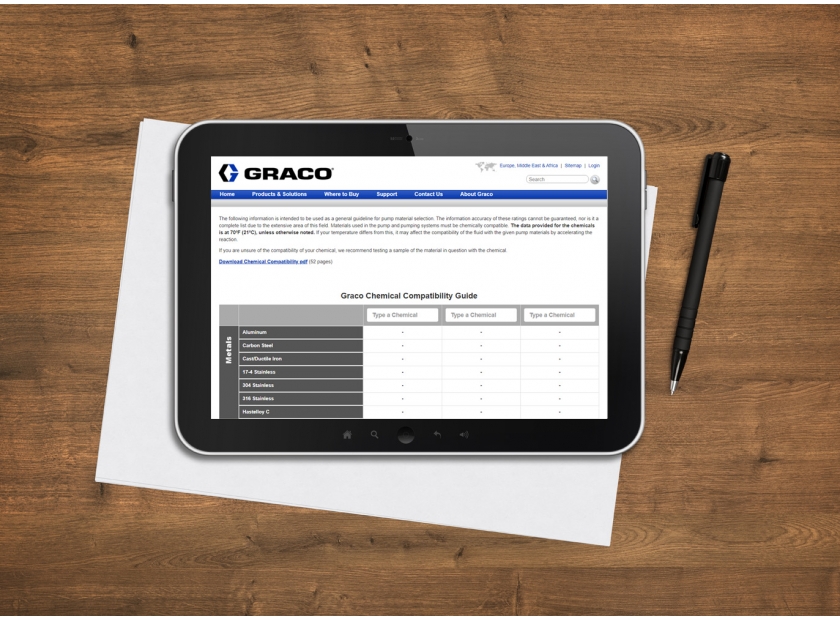

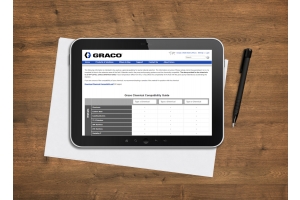

Materials used in your pump and pumping systems must be chemically compatible with the fluid being transferred. Get this mix wrong and you'll not only reduce the lifespan of your pump but you'll risk corrosion and pump failure. Graco's Chemical Compatibility Guide is an essential tool to help ensure that that you select the right pump for your application.

- Posted: January 12, 2021Categories: Sanitary Pumps BlogRead More

These four characteristics should guide your decision

Proper ingredient transfer equipment is crucial in maintaining optimal efficiency and high product quality while balancing operating costs. Food and beverage processors have a difficult task making purchasing decisions when installing new equipment or upgrading outdated equipment. A four-ingredient recipe exists to select the right pump technology for food and beverage applications.

Food and beverage processing has no shortage of options for material pumping. The options can seem overwhelming, from the industry’s new twin screw pumps, the reliable rotary lobe pumps, the adaptable electric and air-operated diaphragm pumps, the powerful piston pumps, and so on. There is a configuration available in the market to meet a user’s needs. The following considerations will steer you in the right direction.

1. Flow Rate

The volume flow rate is determined by multiplying material velocity and tubing size to